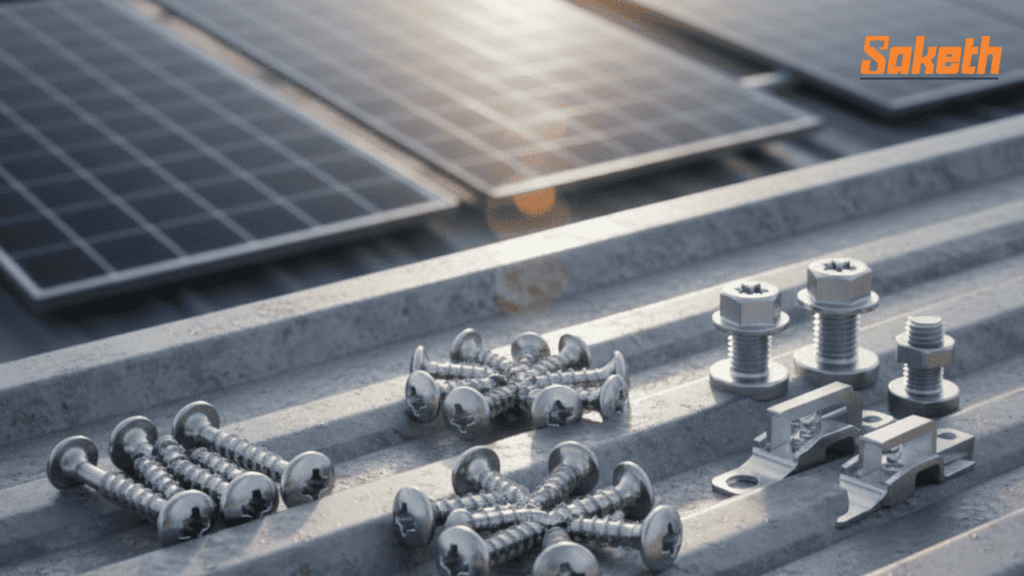

With the global shift toward renewable energy, solar panel installations are growing rapidly across residential, commercial, and industrial sectors. While most discussions focus on solar panels, inverters, and efficiency ratings, one essential component is often overlooked: screws and fasteners.

Choosing the best screws for solar panel mounting systems ensures long-term performance, structural safety, and resistance against harsh outdoor conditions.

Mounting hardware plays a crucial role in holding solar panels securely to rooftops, metal structures, and ground-mounted frames. The wrong type of screw can lead to corrosion, panel misalignment, water leakage, and even system failure. This is why selecting the right fasteners must be a top priority for solar contractors and engineers.

In this guide, we cover the best screws used for solar panel mounting systems, their applications, and the key factors to consider before choosing them.

1. Stainless Steel Screws (Grade 304 & 316)

Stainless steel screws are the most widely preferred choice for solar installations due to their excellent corrosion resistance. Solar panels are exposed to rain, UV radiation, humidity, dust, and varying temperatures. Stainless steel, especially Grade 316, performs exceptionally well in coastal and industrial regions where corrosion levels are high.

Why they’re ideal for solar installations:

- Excellent rust and corrosion resistance

- High durability and long service life

- Suitable for rooftop and ground-mount systems

- Withstands temperature variations and moisture

- Perfect for rails, brackets, clamps, and frame connections

Best use cases:

- Coastal areas

- Industrial zones

- Locations with high rainfall or humidity

2. Self-Drilling Screws for Metal Structures

For mounting solar panels on metal roofs, purlins, and beams, self-drilling screws are the most efficient choice. They eliminate the need for pre-drilled holes because the drill bit is built right into the screw tip.

Advantages:

- Faster installation

- Strong hold in metal surfaces

- Reduced labor cost

- High pull-out strength

- Ideal for industrial and commercial metal roofs

Most self-drilling screws are made of hardened carbon steel and coated with anti-corrosion coatings like zinc, zinc-aluminum, or epoxy for extra protection.

3. Self-Tapping Screws for Wooden Structures

Solar installations on wooden surfaces require self-tapping screws that can cut their own threads as they go in.

Benefits:

- Suitable for wooden rafters and battens

- Strong grip and secure locking

- Prevents loosening from vibration

- Easy installation

These screws are especially useful for rooftop residential solar projects mounted on wooden frames.

4. High-Tensile Bolts and Screws for Structural Frames

When dealing with heavy solar mounting structures or large ground-mount solar farms, high-tensile screws and bolts (Grade 8.8 / 10.9 / 12.9) are crucial. They ensure the stability of the entire structure under wind loads, storms, and mechanical stress.

Why choose high-tensile fasteners?

- Exceptional strength and reliability

- Suitable for large-scale solar projects

- Necessary for heavy-duty frames and foundations

- Safe for high-wind and high-load regions

These screws and bolts are commonly used in mounting rails, panel frames, and large steel supports.

5. Galvanized Screws for Budget-Friendly Solar Installations

For projects requiring cost-effective fasteners without compromising basic durability, hot-dip galvanized screws are often used.

Key advantages:

- Economical

- Good protection against rust

- Suitable for medium-duty installations

- Widely used in residential solar rooftops

Though less corrosion-resistant than stainless steel, they still perform well in most environments.

6. Solar Mounting Screws with EPDM Rubber Washers

For rooftop installations, especially metal sheet roofs, screws with EPDM washers are essential.

Purpose of EPDM washers:

- Prevent water leakage

- Absorb vibrations

- Enhance grip on uneven surfaces

- Improve long-term stability

These screws are crucial for ensuring the roof remains leak-proof even after years of exposure.

How to Choose the Best Screws for Your Solar Installation

Here are the top factors to consider:

Environment & Weather Conditions

Coastal? Industrial? High humidity? Choose 316 stainless steel.

Type of Roof or Structure

- Metal roofs → Self-drilling screws

- Wood structures → Self-tapping screws

- Heavy-duty frames → High-tensile screws

Corrosion Resistance Requirement

Stainless steel > Galvanized > Zinc-coated.

Load-Bearing Capacity

Ground-mounted and large solar farms need high-tensile fasteners.

Warranty Expectations

Solar panels last 25–30 years, so the screws must match this lifespan.

Conclusion

Choosing the best screws for solar panel mounting systems is essential for long-term reliability, corrosion resistance, and structural safety. Whether you’re working on a residential rooftop or a large industrial solar plant, selecting the right fastener ensures a durable, efficient, and low-maintenance installation.

Stainless steel screws, self-drilling screws, high-tensile fasteners, and EPDM-sealed screws all play critical roles in securing solar systems for decades. As the renewable energy sector expands, investing in premium-quality screws from a trusted manufacturer like SSSIL guarantees superior performance and peace of mind.