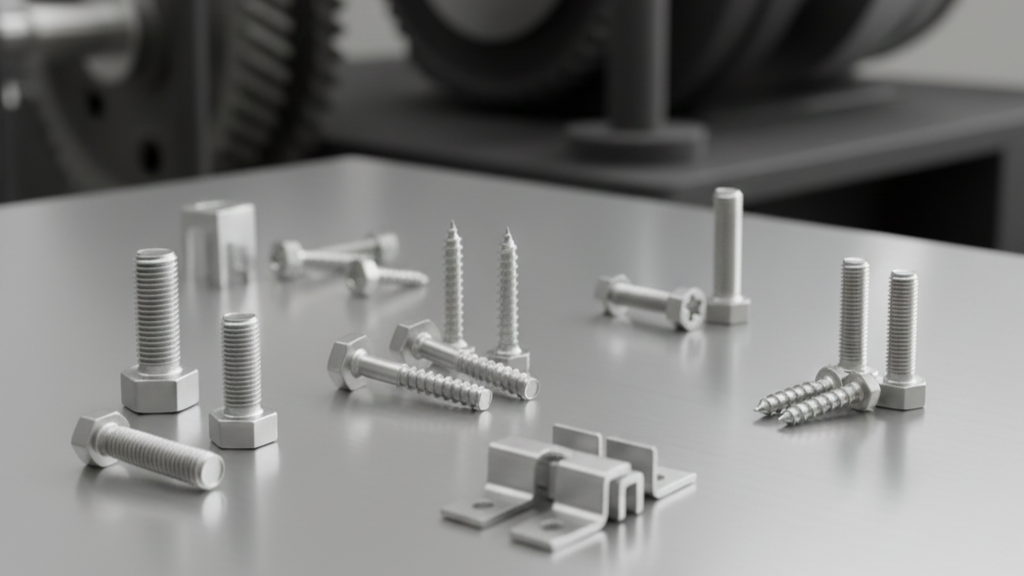

When we think about machinery performance, we mainly focus on motors, gears, and structural components. But one crucial element that directly affects the lifespan of any machine is often overlooked—the quality of screws and fasteners used in the assembly. Whether it’s industrial equipment, construction machinery, automotive systems, or heavy-duty manufacturing units, screws play a vital role in holding everything together.

Low-quality screws can lead to premature wear, misalignment, breakdowns, and even catastrophic machinery failure. On the other hand, high-quality screws enhance structural integrity, reduce vibration damage, and ensure safe, long-lasting operation. This blog explains how screw quality impacts machinery life and why choosing the right fasteners is essential.

1. High-Quality Screws Ensure Structural Stability

Screws act as the backbone of machinery. They secure parts, join components, and maintain overall structure.

Poor-quality screws often fail under load, loosening over time and causing the machine to lose stability.

Impact on machinery:

- Parts become misaligned

- Increased mechanical stress

- Higher risk of component failure

- Reduced overall structural rigidity

High-strength, precision-built fasteners maintain their grip and hold components in place even under extreme operational pressures.

2. Reduces Vibrations and Mechanical Fatigue

Machinery is constantly exposed to vibration—especially in sectors like manufacturing, automotive, and construction.

High-quality screws are designed to resist vibration-induced loosening.

Benefits:

- Keeps assemblies tightly secured

- Prevents micro-movement between components

- Reduces friction and wear

- Extends equipment lifespan

Fasteners with proper thread design, hardness, and coating significantly minimize fatigue failure.

3. Prevents Corrosion and Environmental Damage

One of the biggest reasons machinery fails prematurely is corrosion. Moisture, chemicals, and harsh weather can quickly degrade low-quality screws.

High-quality screws prevent issues like:

- Rust formation

- Thread weakening

- Surface wear

- Structural compromise

Stainless steel, galvanized, and zinc-coated screws provide long-term protection in industrial environments, ensuring the equipment remains safe and reliable.

4. Supports Higher Load-Bearing Performance

Heavy machinery demands fasteners that can withstand high tension, shear forces, and mechanical loads.

Low-grade screws typically deform, crack, or shear off under stress.

Using high-quality screws ensures:

- Better load distribution

- Stable operation under high pressure

- reduced risk of sudden breakage

This is especially critical in high-impact equipment such as hydraulic machines, drilling systems, cranes, and manufacturing lines.

5. Improves Safety and Reduces Breakdowns

Faulty screws are a common reason for unexpected equipment failures, downtime, and safety incidents.

High-quality screws help avoid:

- Loose joints

- Component collapse

- Machinery accidents

- Production halts

Quality fasteners improve operational safety, helping companies reduce maintenance costs and avoid costly shutdowns.

6. Enhances Operational Efficiency

Even minor screw failures can create misalignment that affects the machine’s overall performance.

Precision-engineered screws maintain accurate positioning of components.

This results in:

- Smooth and efficient operation

- Fewer mechanical disturbances

- Better energy efficiency

- Longer service intervals

Well-designed fasteners ensure machines operate at their peak for years.

7. Reduces Maintenance Costs Over Time

Increased durability of screws translates directly into reduced maintenance requirements.

High-quality screws resist wear, temperature fluctuations, and chemical exposure much better than cheap alternatives.

Benefits include:

- Fewer replacements

- Lower repair costs

- Increased uptime

- Long-term savings

Investing in superior fasteners leads to major cost reductions across the machinery’s lifespan.

Conclusion

Screw quality has a profound impact on machinery life. Every fastener plays a critical role in maintaining structural integrity, safety, performance, and durability. Using high-grade, corrosion-resistant, and load-tested screws ensures that your machinery performs flawlessly and remains operational for years.

For industries where reliability and performance matter, choosing the right fasteners isn’t optional—it’s a long-term investment.